Facilities

To book equipment or make an enquiry, please email the contact listed under the relevant facility below. If you are interested in collaborating with us on a project, please contact the Exeter Innovation team.

Imaging suite

Location: Harrison Building, Streatham Campus

Contact: Dr Hong Chang

The imaging suite provides analytical services to internal, external and industrial clients for experimental applications at micro and nano scale. It contains cutting-edge equipment for microscopy and characterisation. It is designed specifically for the analysis of nanomaterials, thin films, bulk materials, composites, polymers and biological materials. The facilities are used for research and industrial projects, but also for undergraduate and postgraduate teaching and project work. For more information visit the imaging suite webpage.

Scanning Electron Microscopy (SEM) with Energy Dispersive Spectrometry (EDS) |

Our SEM has a secondary electron detector and backscattered detector, enabling high magnification images of surface topography and atomic number contrast. In addition, there is an environmental chamber, which allows the non-conductive samples to be imaged without specific preparation. The powerful EDS allows chemical composition information of the materials to be identified in the form of point analysis, line analysis or elemental mapping. It is an important tool for research at nanometer scale, in nanomaterials and biomaterials. |

Transmission Electron Microscopy (TEM)/Scanning Transmission Electron Microscopy (STEM) |

The JEOL 2100 TEM/STEM is a powerful facility that generates atomic resolution images of phases, grains, and defects with lattice imaging on a sub-nano scale. The electron diffraction allows unit cell parameters, orientation and orientation relationships to be identified. |

X-ray diffractometer (XRD) |

The Bruker D8 advanced XRD is capable in analysing samples of powders, bulk and thin film samples for phase composition (phase ID), quantitative phase analysis, unit lattice parameters, crystal structure, and average crystallite size of nanocrystalline. The combined X-ray-reflectometry (XRR) is useful when analysing film thickness. During the heating stage, the material phase change can be characterised in-situ so that analysis can take place. |

X-Tek Bench Top Computer Tomography (CT) 160 Xi |

The X-Tek CT can observe the internal structures of 2D and 3D imaging samples without having to cut the samples. It is ideal for both small and large samples, for defect analysis, porosity analysis or phase analysis (different densities) and with a resolution of down to 3 micron meters. |

Focused Ion Beam (FIB) |

The Nova 600 FIB from FEI is a powerful dual beam unit, that combines an electron beam and ion beam. It has high resolution standard scanning electron microscopy, scanning ion microscopy, as well as ion beam and electron beam lithography. It can deposit materials such as Pt, W; remove materials (etching/milling); and prepare samples in-situ and site specific, i.e. cross-section of materials. It enables sample preparation, imaging and analysis to be completed in-situ in one unit. |

Atomic Force Microscopy (AFM) |

The Bruker Innova AFM is a versatile tool that is used for the characterisation of topography of surfaces providing true three-dimensional surface profile, with sub nanometer resolution, on a small area of approximately 90 micrometer by 90 micrometer square maximum. Applications include measuring thin layer thickness, surface roughness, high resolution images, as well as biological applications. It can also measure the magnetic properties, the conductivity, as well as electrostatic properties of the samples. |

Other imaging facilities

Location: Geoffrey Pope Building, Streatham Campus

Contact: Dr Sam Stevens

Scanning Electron Microscope (SEM) (JEOL-JSM-6010LV Plus) |

This research-level SEM is for undergraduate research use. The instrument is situated in its own dedicated undergraduate (imaging) suite within the Geoffrey Pope building. The SEM is a Low Vacuum System, which allows non-conductive samples to be imaged. It is fitted with both a Secondary Electron Detector (SED) and a high sensitivity Backscattered Electron Detector (BED) providing high resolution images of samples down to the nanometer scale together with 16 Megapixel image capture, affording an outstanding imaging capability. The instrument is also fitted with X-ray EDS, which allows fast quantitative elemental mapping of samples using energy dispersive X-ray spectroscopy (EDS). The SEM is a user friendly instrument with excellent supporting software, it is controlled both manual control panel and PC Touchscreen monitor. It has wide applications across disciplines. |

Scanning Laser Confocal Microscopes (Leica SP8) |

These microscopes are in the Biosciences teaching lab and are open to any trained user: both undergraduate and research alike. It is particularly useful for real-time viewing of microscopic features of living tissues (leaves and the fungi that may infect them, for example) in three dimensions. Most living cells fluoresce in some way or can be made to fluoresce using dyes. Lasers of varying colour are focused into sharp points and scanned faster than the human eye can detect over the surface of the sample and their fluorescence is detected. Different types of cells and their associated structures fluoresce differently and a compositional as well as topographic micrograph may be taken. Refocusing the rastering laser allows images in a sequence above or below the current plane of focus to be collected, producing three-dimensional representations. All this may be performed in real time increasing the scope of potential experiments. The value of this particular microscope is the range and specificity of colours available: both in terms of the laser source and detection of emitted light from the sample. |

Bioimaging unit

Location: Geoffrey Pope Building Floor 1, Streatham Campus

Contact: bs-bioimaging@exeter.ac.uk

The Bioimaging unit provides state-of-the art instrumentation and experienced staff to assist researchers and students to obtain high quality microscopy. For further information on the facilities and to book equipment please visit the Bioimaging unit website.

Facilities include:

- Jeol JEM 1400 transmission electron microscope with Gatan ES 100W CCD camera;

- Tomography software and Jet Propane/Freeze substitution prep;

- Jeol JSM 6390 LV scanning electron microscope with SEI/BSI/LV detector modes and Gatan Alto 2100 Cryo prep;

- Olympus Ix81 Inverted wide field fluorescent microscope with cool snap HQ2 CCD camera, TIRF system and Metamorph software;

- Zeiss 510 Meta confocal microscope with blue diode, argon/2 and HeNe lasers, environmental chamber and Axiovert 200M Inverted microscope.

Collaboratory

Location: Geoffrey Pope Building, Streatham Campus

Contact: Heather Ford

Zeiss Primo Star Microscope |

The microscope has a wide variety of study uses, but its primary mode of use is for teaching biology modules on the Natural Sciences programmes. It is connected to a HD camera, allowing students and staff to view the microscope imagery remotely via ipad, and also through the lab display screens. |

Spectrometers |

We have two types of spectrophotometers in the Collaboratory lab: Light Wave II WPA diode array spectrophotometer and UV/Vis Jenway 7315 Scanning spectrometer. These are commonly used to measure the reflectance of solutions which can then determine properties within a testing material. Both use 1cm cuvettes which are placed in the path of a light beam, and the spectrometer provides a result depending on the wavelengths absorbed by the solution or material being tested. |

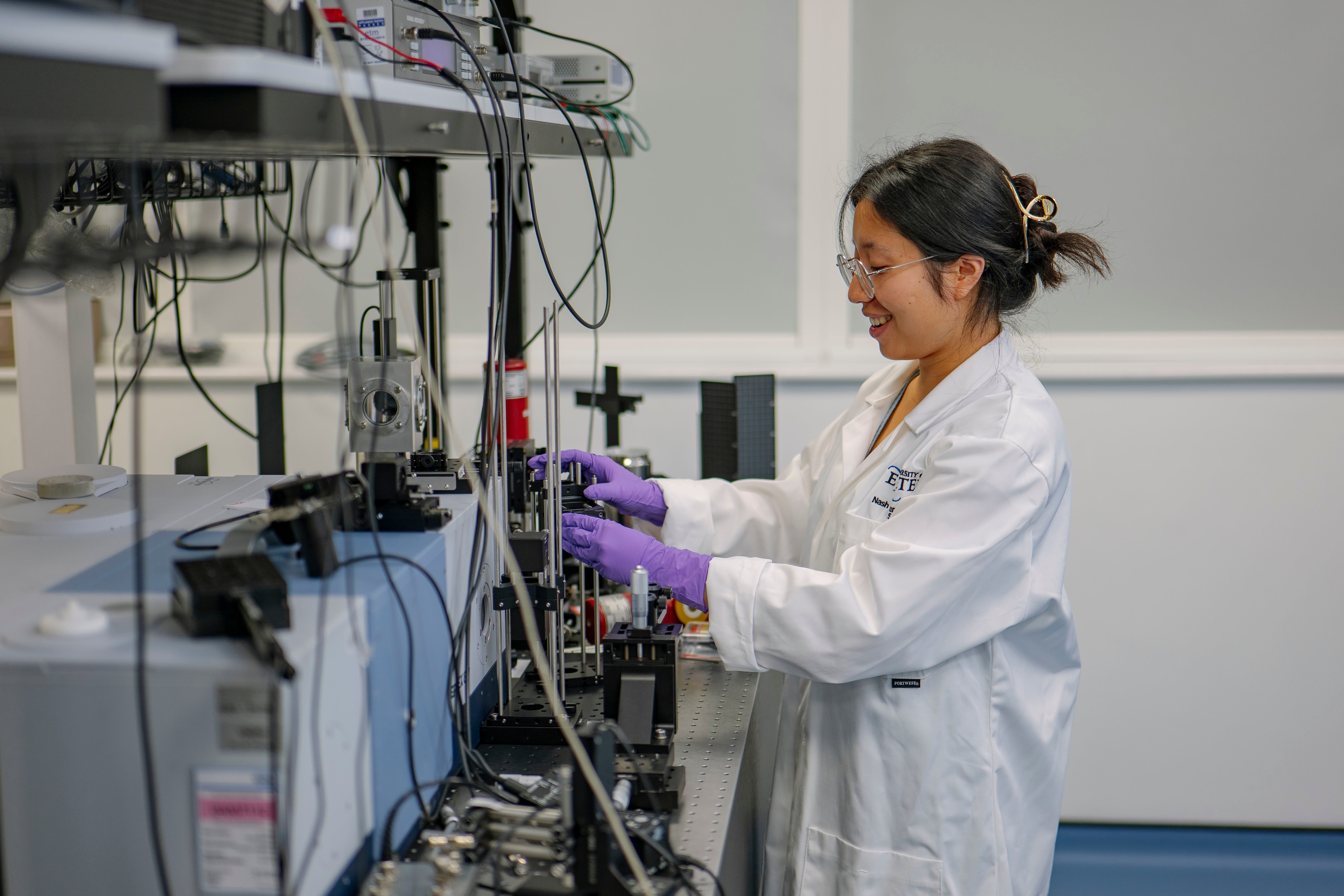

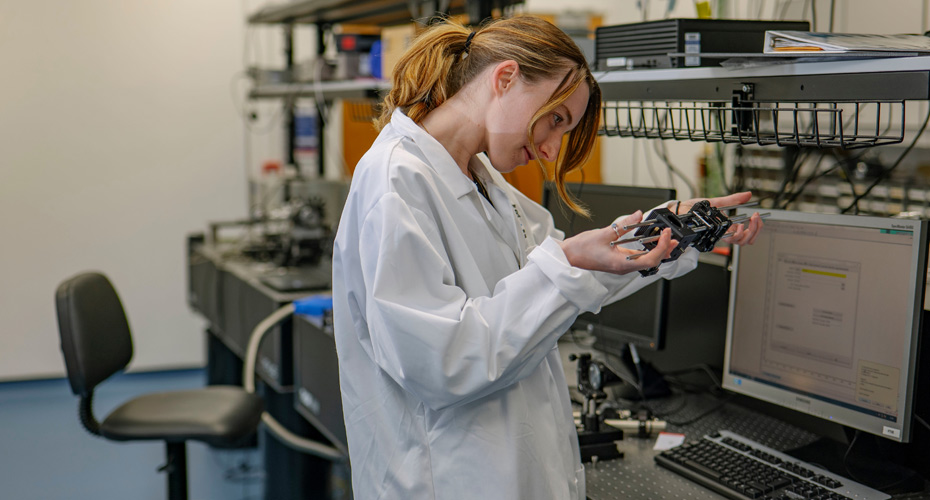

Nanofabrication

Location: The Alex Savchenko Centre for Nanoscience, Physics Building, Streatham Campus

Contact: Mark Heath

Nanofabrication is the process of manufacturing devices with dimensions measured in nanometers. The Alex Savchenko Centre is a purpose-built semiconductor-type cleanroom for nanofabrication. It has advanced air-condition control of temperature and humidity throughout the working areas. It is predominantly used by research staff, however it can be used for student project work if required. We have worked successfully with commercial and academic partners and are keen to continue with further projects and collaborations.

Lithographic systems

These facilities allow the user to transfer a pattern of choice ranging in size from 10nm to 150mm to a substrate.

NanoBeam NB4 Electron Beam System |

A state-of-the-art 30kV to 100kV dedicated electron beam lithography tool capable of producing 10nm lines (±15%) across a 250um Field using a 2nA Beam. Each of the fields can be accurately positioned and joined together using a 195mm x 195mm precision stage controlled by a 0.31nm (l/2048) laser interferometer system. It has a 20bit, 55Mhz pattern generator with 1nm resolution (beam-step) at a 1mm field size. The system is capable of directly writing on a variety of samples ranging from 5mm to 150mm square, including optical mask plates. |

Durham Magneto Optics Microwriter ML Laser writer |

Optical system capable of handling 200mm substrates and utilising three 405nm lasers with nominal beam widths of 0.6µm,1.0µm and 5.0µm. Maximum write speeds are of the order of 180mm²/ minute using the 5µm laser. |

Karl Suss MJB4 Optical Mask Aligner |

Wafer and substrate handling up to 100mm with Soft, Hard And Vacuum contact exposure modes using up to 5" mask plates. |

Deposition systems

These facilities allow the user to deposit thin films like gold, chromium and silicon dioxide onto the patterned substrate.

Kurt J Lesker Evaporation System |

A custom designed Combined Electron Beam and Sputtering Evaporation System with substrate RF DC biasing and the capacity to oxidise samples during the deposition process. It has a 10kW Ebeam power supply which means it is capable of evaporating a wide range of materials. It has a 3" diameter sputtering target for enhanced deposition uniformity and automatic operation using a recipe driven computer control system. |

HHV Auto306 Thermal Evaporator |

A standard thermal evaporator with 4 sources generally set up for Cr/Au, Au and Al electrode deposition. Minimum base pressure 2x10-7 Torr. |

Moorfield nanoPVD S10A |

Benchtop sputtering system with 3x2" magnetron sources and ability to do RF or DC sputtering. Materials include dielectrics (SiO2, Al2O3) and metals (W, Ta, Ti). |

Etching systems

These facilities use RF generated plasmas using various process gases to either clean substrates or dry etch hard materials like graphene and silicon.

LS Designs RIE 80 Etching System |

An automatic computer controlled RF and ICP Reactive Ion Etching system fitted with a Laser Etch Penetration Depth (EPD) monitoring system to accurately control etch depths. It has the facility to use six different process gases so is very versatile and can easily be adapted for future research work. Typical process gases are O2, Ar, CHF3 and SF6. |

LoadPoint Micro Ace 3 Dicing Saw |

Automated dicing system capable of cutting Silicon, Quartz and Sapphire substrates up to 6" diameter. Stage resolution down to 1 micron. |

K&S 4123 and 4700 Wire Bonders |

Manual wedge bonding utilising 25 micron gold and aluminium wire for electrical connections from sample to chip carrier. |

Critical Point Drier |

Uses liquid CO2 to dry delicate samples such as suspended graphene. |